What is Aluminum wiring? How aluminum wiring can be dangerous?

Aluminum wiring was used quite extensively in residential homes between 1965 and the late 70s. After the late 1970's aluminum wire became unpopular, and it was not until the early 1990's that it started to be used again, though still not as much as copper. When installed and used in its proper application as per the CEC (Canadian Electrical Code), it will operate as safely as copper wiring.

The wiring that is of major concern is the single strand solid aluminum wiring, connected to the smaller branch circuits supplying receptacles, switches, lights, and appliances such as dishwashers, furnaces, etc. Corrosion of the metals in the connection, particularly the aluminum wire itself, causes increased resistance to the flow of electric current and that resistance causes overheating. Most modern homes have some aluminum wiring, including the main service wires, and the heavier 240 volt circuits that feed other major appliances, such as ranges and air conditioners. The higher voltage wiring does not present the same risk as 15, 20 and 30 amp circuit wiring.

Aluminum has different properties than copper and the two react differently by expanding and contracting when under electrical load which may cause the connections to become loose. When the connections become loose this can result in sparking, arcing, oxidation and heat buildup which can cause the possibility of a fire in the area of the electrical box etc.

Aluminum wire oxidizes more quickly than copper wire.

Another issue is the joining of aluminum wire to copper wire. As aluminum and copper are dissimilar metals, galvanic corrosion can occur in the presence of an electrolyte and these connections can become unstable over time.

In order to address this problem of aluminum wire connections during this time, the industry came out with dual rated connectors that would accept either copper or aluminum wire. Items with the dual rating were indicated by a marking such as CU-AL, CO/ALR, AL/CU or something similar. This solution offered some relief to the problem, and with the many fires that had occurred its use in the industry basically stopped in the late 1970's. During this time such things as anti oxidants were developed that would be applied to connections to reduce the oxidation of the connectors but this involved continual maintenance and was too time consuming and therefore not a very favorable solution.

How can you tell when aluminum wiring can become a problem?

As mentioned above, aluminum wire is safe...it is the connections that cause the problem.

Aluminum wiring have been a leading cause in house fires in which people have been killed. There are several possible reasons why these connections failed. In fact, the US Consumer Product Safety Commission reports that homes with aluminum wiring are 55 times more likely to have fires as a result of poor electrical connections.

Signs to look out for:

- crackling noises

- see sparks in your electrical outlets

- an item is hotter than it typically should be to the touch

- breakers or fuses continually trip or blow

- intermittent power or circuits that simply don't work

- equipment or wire that is damaged

- discoloration cover plates

- the smell of burning plastic or rubber

- flickering lights

- smoking outlets, switches, or lightings

What should you, the homeowner do?

If you have noticed any of the trouble signs, have a qualified electrician determine whether the problem is caused by deteriorating aluminum connections. Do not try to do it yourself. You could be electrocuted or you could make the connections worse by disturbing them. If you are not certain whether your home has aluminum wiring, you may be able to tell by looking at the markings on the surface of the electric cables which are visible in unfinished basements, attic, or garages. Aluminum wiring will have AL or Aluminum marked every few feet along the length of the cable.

What is the solution out there when dealing with aluminum wiring?

There are two solutions:

- Rewire the house.

A project like this can cost between $8000 to $12000. It will take approximately 1-2 weeks . We always recommend the full replacement of aluminum wiring.

- Rejuvenate the connections.

This is the cheapest way to make your aluminum wiring safe. This project can take 1 to 3 days.

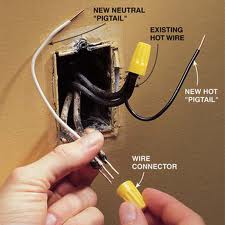

The most common method to rejuvenate the connections is referred to as pig tailing. This would entail us installing a small piece of copper wire to the aluminum wire and terminate the copper wire portion of the cable to the device. In order to pig tail the two different wires together we have to use an appropriate connector (dual rated) that is approved for use in Canada.

Aluminum wiring can create many headaches for homeowners nowadays, whether it is having to deal with insurance companies mandating it to be brought up to current safety standards, or having to deal with the continual burnouts and circuit failures. Mapleleaf Electric Inc has extensive experience with aluminum wiring and can inspect and correct your wiring to current standards. Upon completion of our repairs we will coordinate an inspection with the Electrical Safety Authority who will issue a Certificate of Inspection.

FOLLOW THESE LINKS FOR THE DETAILED INFORMATION YOU NEED

To provide you the most accurate and comprehensive information on aluminum wire we have provided links below here on our web page to the most authoritative sources available.

If your home has knob and tube wiring, or aluminum wiring, and you are concerned about the safety of your electrical system, contact Mapleleaf Electric Inc and arrange for an assessment.

Copyright © 2014 Mapleleaf Electric Inc. All rights reserved.

ECRA/ESA 7005787